HOT BLOCK HEAT ABSORPTION PUTTY

WHY YOU NEED IT

- Stops heat up to 3000 F

- Constant protection for valves, sensors, fittings and all heat sensitive components

- No permanent residue left behind; wipes off with water

WHY IT’S BETTER:

- Can be reused limitless times

- Completely non-toxic to the copper tubing; no

chemical reaction - Even if it dries out, you can add water to re-energize it and it maintains the same level of performance.

FLAME RESISTANT MAGNETIC BLANKET

- Reinforced slit to slip over valves and line sets

- Only one currently on the market with magnets

ALUMINUM COIL REPAIR: ALLOY SOL RODS &

ALLOY SOL FLUX

WHY YOU NEED IT

- Aluminum is here to STAY. Manufacturers are using aluminum over copper moving forward.

- Fixing aluminum tubing or micro channel is one of the most intimidating jobs that technicians have for fear of more damage. Solderweld AlloySol products help build confidence.

- The easiest Aluminum Repair Kit on the market; almost foolproof

- Our Flux changes from white to clear, visually indicating when you’re at temperature to start soldering.

- Lowers the chances of overheating the aluminum base metal and causing significant damage resulting in leaks

- Alloy Sol is a complete repair not a patch. It’s a 30,000 PSI repair.

- If a coil replacement is 2 weeks out or 2 months out, Solderweld is the solution to get customer back up and running.

WHY IT’S BETTER:

- Alloy SOL flows at a THIRD of the melting temperature of the competition: 600 F vs. around 1000 F (Aluminum melts around 1200 F)

- The Competition’s Flux is built into the rod, so you have to heat the aluminum first then add the rod.

- With ours, you add the Flux first, heat it until it changes color which shows you’re ready to add the rod.

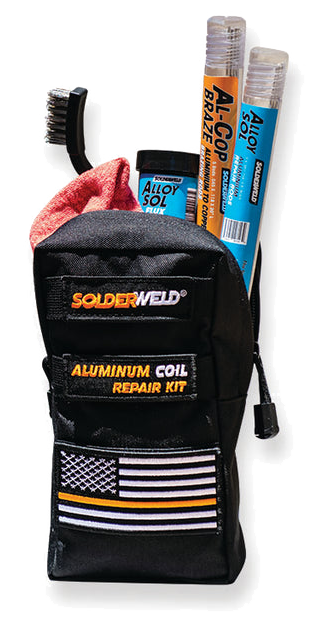

ALUMINUM COIL REPAIR KITS (BACKPACKS)

- Everything you need to make an aluminum repair; convenience

- Nothing else currently like it on the market.

AL-COP: ALUMINUM TO COPPER BRAZING RODS

WHY YOU NEED IT

- The easiest aluminum to copper in the industry

• Also works for aluminum to brass

• Low temp flow rate for safer brazing of

aluminum to copper

• Flux core rods

WHY IT’S BETTER:

- One of the first solutions on the market to address the aluminum coil to copper joint leakage problem

Solderweld

You Bring the Heat, We’ve Got the Rest Covered